Cold Process Handmade Soaps … how are they different?

There are many different cold process handmade soaps on the market. What makes them different? I recently attended a presentation where we talked about misconceptions in the market place. Misconceptions that could be detrimental to a business. The first thing I thought of was that some people think that all cold process handmade soaps are the same. I’ve heard people walk past my stall and say, “Oh I bought some of those at a market last week”. I think to myself at the time “well how is that possible as I wasn’t at that market last week”. So how are cold process handmade soaps different?

It’s also important to differentiate between what is cold process soap and what might be a melt and pour product. The cold process method is much more technical starting from scratch with caustic soda, water and oils. Melt and pour is a ready made product that is melted down before adding other ingredients.

Just like making a cake, cold process soap making requires a recipe. Like making a cake the end product is only as good as the recipe. So the first thing required is a good recipe to make a good soap. When I first thought about making soap I had bought various handmade soaps from different markets all over the world. Some were better than others.

What did I want in a soap?

I wanted to make a soap that was hard, wasn’t drying on the skin, and the scent would last. For that to happen I had to research the oils to add to my soap recipe.

Oils

Olive oil is a well known soap oil. It is moisturising but has low cleansing properties ie it doesn’t provide a great lather. Olive oil soaps can be fairly soft when first taken out of the mold and require a lengthy (upt to a year) cure time. When I first started making soap I made some 100% olive oil soaps (castile). While they were quite nice to use initially, they had very little lather and became quite soft if not aired sufficiently between uses. Additional oils had to be added for a quicker cure time and give a nice cleansing lather.

Coconut Oil is a superior oil in soapmaking and creates big beautiful bubbles. It contributes to a firm bar but can be drying on the skin if used in too high a percentage. Using no more than 30% coconut oil in a recipe is considered ideal for a soap that isn’t drying.

Sunflower, soybean and canola oils can create a softer soap depending on the percentage used. They should be used in low percentages. These oils are inexpensive but not as stable in soap as other oils. You would expect a soap containing these oils to be a lower price than a soap that contains Macadamia, Hemp or Avocado oils. Macadamia, Hemp and Avocado oils may be more costly but worth adding for their moisturising properties and luscious bubbles. Avocado Oil is one of the few oils that retains its natural properties throughout the soapmaking process. You will notice when using a cold process handmade soap containing avocado oil that it has a beautiful rich silky feel to it.

What about Palm Oil?

Aah the controversial use of Palm Oil! So why do we use Palm Oil in soap? It creates a hard soap, has moisturising properties and creates a rich creamy lather.

The use of palm oil in soap is a very small percentage of the world’s palm oil use. If palm oil were to be replaced by another oil the environmental consequences could be far worse. The World Wildlife Fund website states “Palm oil is a very productive crop and offers a far greater yield at a lower cost of production than other vegetable oils.” To replace the equivalent in palm oil with say olive oil would require a much larger plantation area. Our palm oil supplier is a member of and complies with the Roundtable on Sustainable Palm Oil (RSPO) and follows the associated principles and criteria. You will find links and further information in our ingredients list.

Butters

Now to the beautiful additives of shea, mango and cocoa butter. These ingredients are used to add something special to a cold process soap and each add their own characteristics. While they may add to the hardness of a soap the benefits are minimal. Due to the high cost I use these ingredients in products that are directly applied to the skin.

Fragrance

Fragrance and the percentage used is another important ingredient to be added to the soap making recipe. It is important to get the percentage right as essential oils will gradually evaporate from the soap over time.

We use quality essential oils at the higher end of the recommended usage. As an example of the quality of oils, one of our most popular scents is rose geranium. Earlier this year it was found that many rose geranium essential oils on the market were adulterated with synthetic additives. We had to seek out a pure rose geranium essential oil. This pure oil was double the price of the original so obviously added to the price of the soap. The differing prices of essential oils can make a huge difference to the price of a soap. For example 500g of lemongrass might be $75 while the same amount of ginger oil may cost $220.00. Essential oils vary in price and quality from supplier to supplier.

Colours

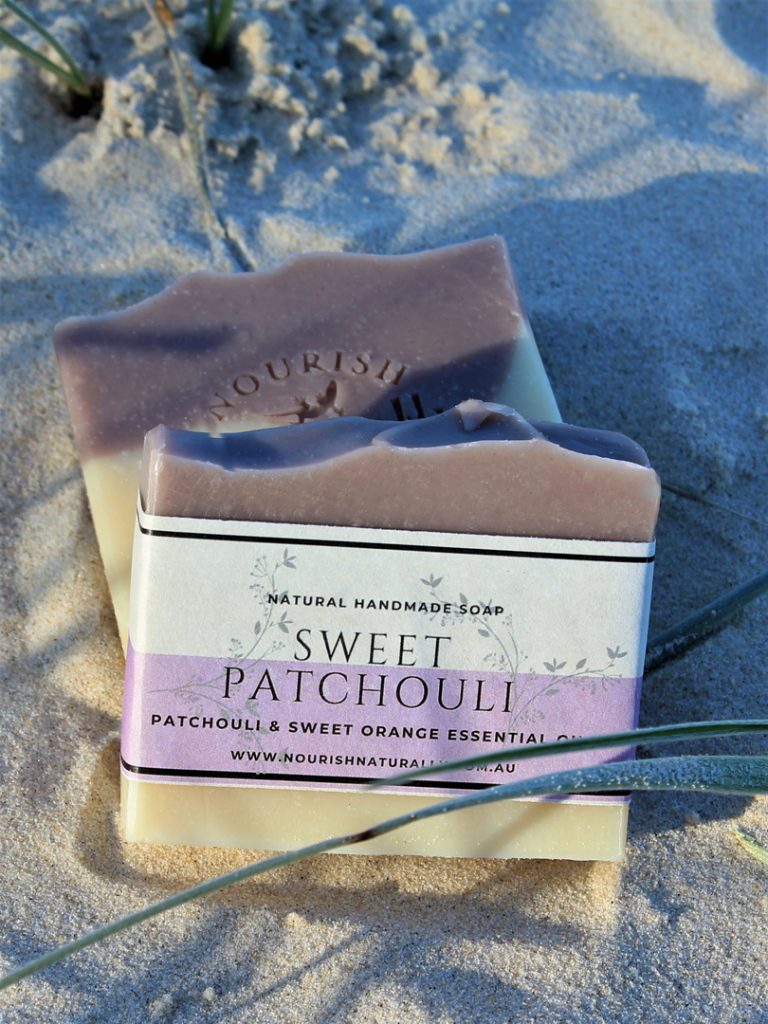

When you look at a soap you can tell straight away if it contains natural colours or not. If a soap is bright purple or pink it is highly likely that it contains synthetic colours. There is a misconception that micas are natural however due to the pigments that are added to get the bright colours available today we don’t use any micas. Some soap makers use micas and other synthetic colours. We use only natural colours such as mineral clays and herbal extracts.

I think that covers how different one soap can be from the next.

If you’ve been inspired to have a go at making soap, why not have a look at our soapmaking kits. Bringing your own personal soapmaking workshop into your home with follow along videos taking you through the whole soapmaking process.

When you’re next shopping for soap, don’t look at it as just another bar of soap! Every cold process handmade soap is different.